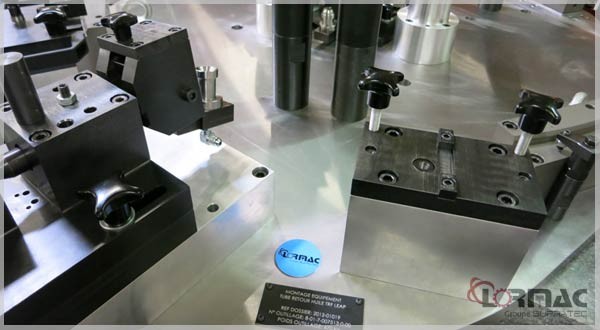

Aircraft casing positioning control installation

Custom control installation designed to verify the transfer of utility pipes into the interior of an aircraft casing.The instrument makes sure there is minimum play between the tubes.

Requirement / To control the positioning of components.

The control problems arising in this application required two sets of measurements. The control installation needed to :- Make sure there is minimum play of “standard” tubes around theoretical points in space.

- Allow a tube and elbow to be checked by the same instrument to verify minimum play.

Solution / Specialised control installation.

- Development and implementation of a specialised control assembly integrating the required devices

- The custom control installation designed by Lormac focused on the functional and ergonomic aspects of the components to be controlled

- The instrument needed to be geometrically accurate in order to be able to precisely measure the positioning of the theoretical points