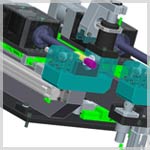

Dedicated pump body machining fixture

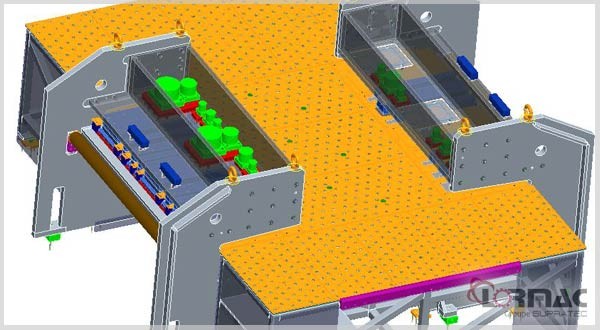

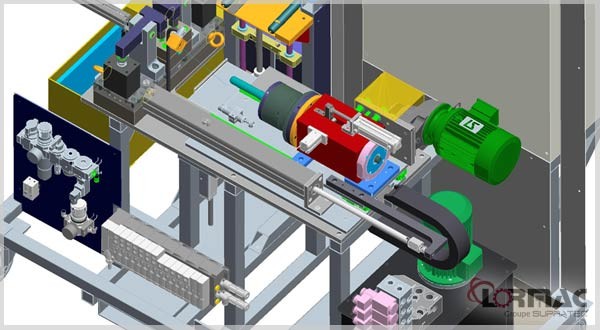

Dedicated machining fixture for working vehicle parts on a palletized machine (2 palettes) two spindles. The design of this custom clamping unit made sure that a maximum number of parts could be machined on each pallet rotation and that the cycle time was optimised.

Requirement / Custom part pick-up and clamping.

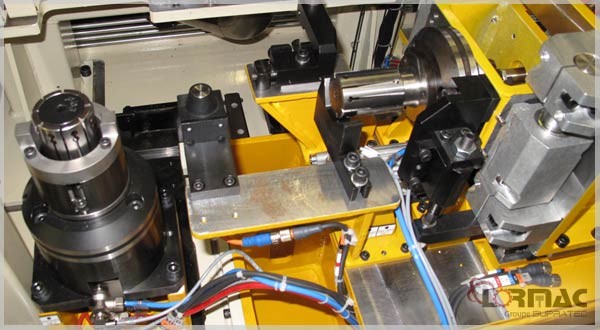

Custom clamping solution adapted to the geometry of the vehicle parts and meeting constraints in terms of productivity and customer quality :- part positioning accuracy (two spindles),

- effective clamping,

- maximum size constraints,

- machining in 5 axes with access to multiple tools.

Solutions / Dedicated machining fixture.

Design, manufacture and optimisation of dedicated machining installations for custom clamping and positioning of parts to be machined :- 2 x 1st OP 4 position installations, both handling 4 axis machining operations: clamping and positioning of 4 parts per tool with holes in the baseplate for pass-through machining.

- 4 x 2nd OP 2 position installations, all handling 5 axis machining operations: clamping of 2 parts per tool.

© 2013 LORMAC Automation – Groupe LORMAC

Conception et réalisation de machines spéciales d’assemblage, montages d’usinage, systèmes hydrauliques, postes ergonomiques, procédés de production automatisés, équipements de contrôle.

© 2013 LORMAC Automation – Groupe LORMAC

Conception et réalisation de machines spéciales d’assemblage, montages d’usinage, systèmes hydrauliques, postes ergonomiques, procédés de production automatisés, équipements de contrôle.