Specialised shrink fitting machine for the assembly of reactor rings. The ring is fitted inside an aircraft casing using a shrink fitting process. The shrink fitting assembly process used in this application involves expanding the receiving part (the casing) by the application of heat to produce a robust assembly.

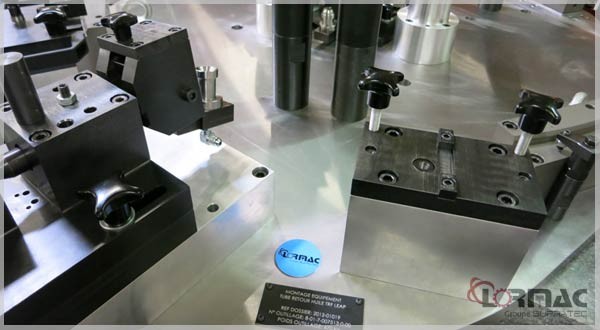

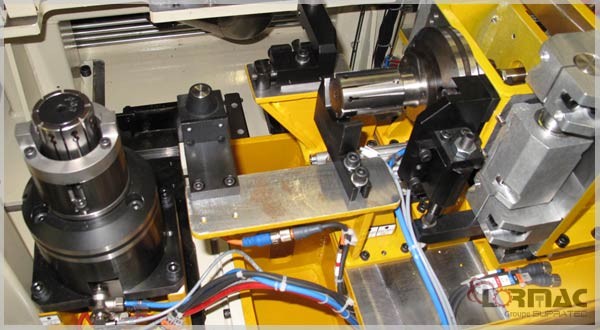

- Custom slide shrink fitting machine

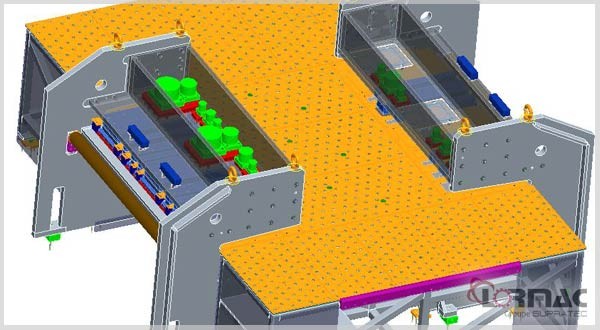

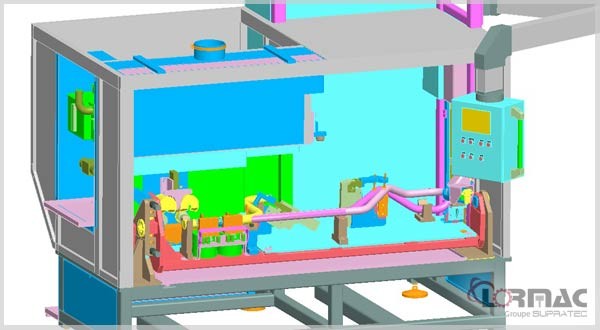

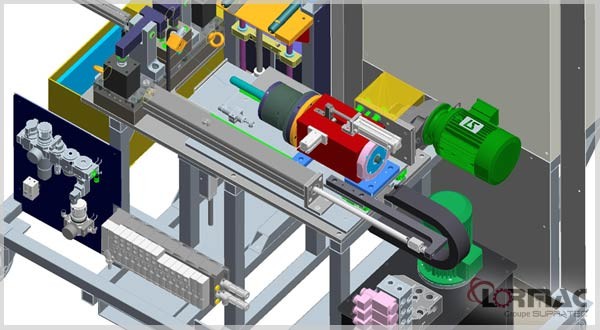

- 3D view: Aeronautic shrink fitting machine

Requirement / A safe installation using a shrink-fitting process.

In addition to very accurate positioning of the components, the customer also required that the installation be extremely safe. As the abradable material is shrink fitted in a very high temperature environment, the machine needed to provide protection for the operator and other persons from the heat generated at the work station.

Solution / A specialised shrink fitting machine and tool.

A custom slide shrink fitting machine with component loading and unloading. When the slide is closed the parts are impossible to touch to prevent risks to the operator; the shrink fitting operation can be performed in complete safety.

Heat is provided by heating collars designed especially for this application.

Shrink fitting operations are controlled using a tactile interface and the assembly machine is easy to use on a day-to-day basis.

The machine’s performance levels /

- Shrink fitting temperature 200°C

- Ø of components up to 1120 mm.

Further information.

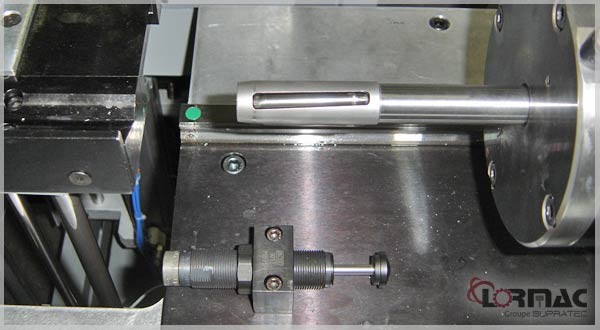

During the turnkey manufacture of this specialised machine Lormac also developed an abradable material pre-stressing system to allow it to be precisely positioned within the casing.

A specialised instrument checks the correct execution of the shrink fit at the end of the process. The custom design of this machine is an illustration of Lormac’s expertise in the manufacture of specialised production machines and tools. Lormac satisfied the safety requirements for the machine during the shrink fitting operation and also used its expertise and technical skills to increase productivity.