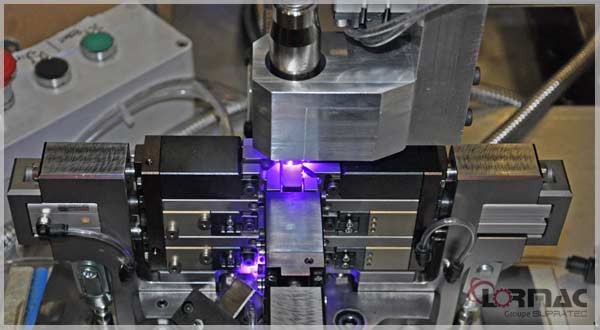

UV bonding machine : automated rotor assembly

Automated UV bonding machine, specially designed to bond ferrites to a rotor axle.This specialised bonding machine combines Lormac’s expertise in manufacturing process automation and the skills of Syneo, a company specialising in industrial bonding.

Requirement / Industrialisation of a new manufacturing process.

Industrialisation of the bonding of 4 or 8 ferrites to the rotors of a motor. Annual production in the order of 100,000 parts. The parts were previously assembled using mechanical techniques and the customer asked us to develop a bonding solution which would improve this process. Lormac and Syneo’s combined expertise allowed us not only to propose an innovative assembly process using adhesives, but also to automate production through the use of an automated bonding machine.Solution / Automated UV bonding machine.

Lormac used their technical expertise to design an automated assembly machine with manual loading and unloading. Once the components to be assembled have been loaded, the rotor is handled by a 6 axis robot at the heart of the automated enclosure. The ferrites are positioned and bonded in place simultaneously when the jaws of the installation close. Operations involving the application of adhesive, bonding, UV curing and concentricity checks result in high productivity levels.The assembly machine’s performance levels /

- A complete cycle time of only 11 seconds,

- Gravity-fed dosing system,

- Automation of the assembly process using a Syneo bonding solution comprising a high-precision volumetric doser and two UV curing lamps.

Further information.

The collaboration between Lormac and Syneo, both subsidiaries of Groupe Supratec, resulted in the creation of an automated bonding machine which completely satisfied a customer requirement for the automation of their production process. Lormac handled all aspects of project management from A to Z. From study to final delivery at the site including design, operator training and shipment of equipment, Lormac provided the customer with a turnkey automated assembly solution.This bonded assembly solution would not have seen the light of day without the combination of skill-sets in bonding and engineering provided by the two Groupe Supratec companies.