Specialised machine for flowdrilling and tapping tubes

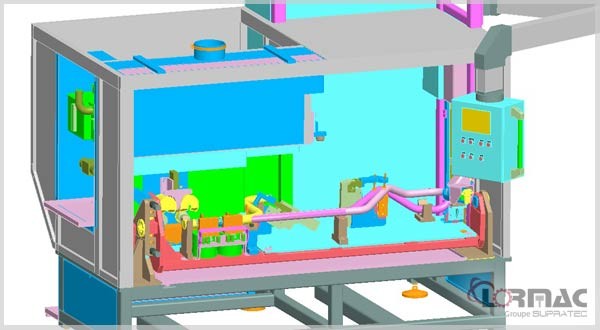

Design of a specialised flowdrilling and tapping machine for the assembly of attachments on to exhaust pipes.

Requirement / Assembly of components on tubes.

Treatment of exhaust tubes to allow additional components to be attached.Solution / Specialised flowdrilling machine.

Custom manufacture of a linear transfer drilling and tapping machine. The hole is created by pushing back and deforming the stainless steel (flowdrilling). This process allows components to be attached without the need for additional inserts.Performance of the specialised flowdrilling machine /

- Automated manual loading and unloading station

- Digitally-controlled part transfer cart

- Component referencing

- Precise machining of materials by deformation

- Smoke extraction

- Dual drilling and tapping operation takes less than 90 seconds