Specialised bolt assembly machine : bolting of cylinder head covers

Automated bolting machine for the assembly of cylinder head covers for the vehicle industry.This bolting station was implemented on a manufacturing line and needed to conform to the productivity and quality requirements stipulated by the constructor.

Requirement / Assembly and control of the operation.

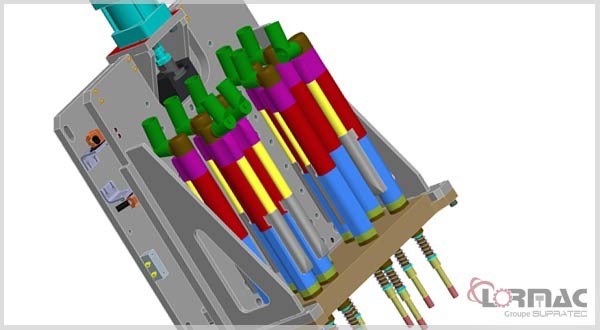

Automated bolting of an engine component (cylinder head cover), with operational checks at the end of the process. Integration of a bolting station on an existing production line.Solution / An automated 9-spindle bolting machine.

Automated bolting machine for the simultaneous assembly of 9 attachment points. In order to conform to the customer’s productivity and quality constraints, Lormac designed a complete turnkey machine comprising:- 1 entirely automated 9 spindle bolting station

- 1 engine referencing lift

- 1 master bolting frequency calibration system

- 1 RFID chip operation counter for part sleds.

The machine’s performance levels /

- Cycle time of 24 seconds

- Simultaneous tightening of 9 attachment bolts

- Checking of 100% of torques and bolting angles

Further information.

Lormac’s expertise in the design of custom assembly solutions allowed them to deliver a specialised multi-spindle bolting machine and tools. The simultaneous attachment of 9 bolts provided time savings and increased the productivity of the vehicle constructor’s assembly line.