Specialised double punching machine

Manufacture and optimisation of a hydraulically powered double punching machine for mass production of a new vehicle in the vehicle construction industry.

Requirement / Industrialisation of a production run.

Automation of vehicle component production, preparation of suspension wishbones.Solution / Specialised double punching machine.

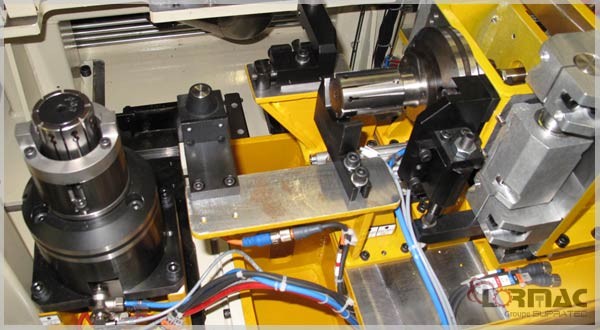

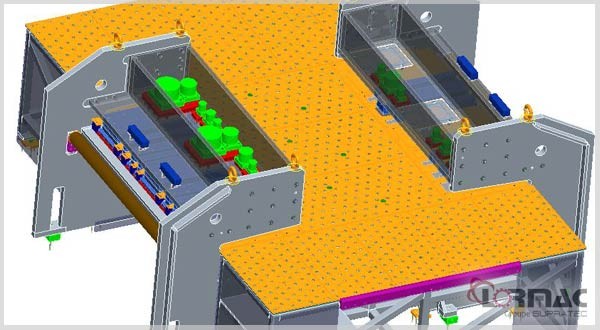

Design of a specialised hydraulically powered double punching machineThe double punching machine’s performance levels/

- Simultaneous punching of 4 holes in 2 symmetrical parts.

- Accurate component referencing

- Expanding hub clamping

- Feeding of parts at the end of the cycle

- Recovery of punched waste materials

Further information.

The integration of a standard punching machine at the core of an engineering process illustrates Lormac’s expertise in the design of custom solutions using standard equipment.Lormac’s experience in the design of specialised machines combined with their internal skill sets resulted in a set of custom assembly procedures designed to overcome automation problems associated with production processes.