Specialised forming machine

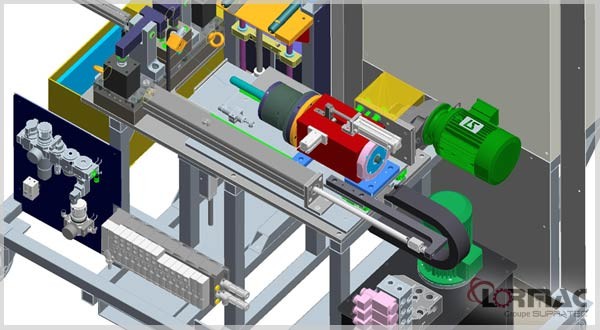

Design and manufacture of a specialised forming machine designed to assemble components on a tube without using connectors.

Requirement / Assembly of components on tubes without the use of connectors.

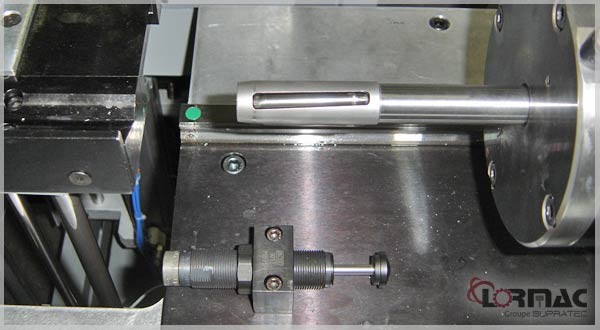

Expansion of one end of a tube to allow attachments to be fitted without the use of connectors.Solution / Specialised forming machine.

The specialised forming machine used in this application expands the tube by swaging (expandable rotating rollers) and is loaded and unloaded manually. Both clamping and transfer systems are hydraulically powered.Performance of the specialised forming machine /

- Flaring operation done in a single pass

- Deformation control (expansion/thickness ratio)