Workholding System, part handling installation design

- Multi-disciplinary team : Design office and technicians specialised in mechanics, electrics, hydraulics, pneumatics and automation

- Full manufacturing : machine shop, metrology shop, assembly, control methods

- Quality and precision : precision adjustments, repeatability of assembly, process cycle times

- Over 30 years experience : vehicles, aeronautics, construction, mechanical transformation …

Examples of products and design of part handling installations, hydraulic grips :

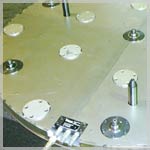

1. Aeronautics hydraulic machining fixture

Study, design, optimisation of a machining installation with hydraulic grip and holding. Double-face machining of an aircraft casing in single operation. Custom gripping and positioning adapted to the specific geometry of the part to be machined...

2. Dedicated vehicle workholding fixture

Dedicated hydraulic machining fixture with custom grip solution for working vehicle parts on a palletized machine. Design and optimisation of several specialised installations with 2 and 4 positions and machining in 4 and 5 axes. Custom crimping and positioning, through-machining...

3. SMED rapid change-out interface

Design and manufacture of a hydraulic SMED interface for the rapid change-out of tools in the machining cell. Single standardised interface for all production machines. Immediate productivity gains...

4. Custom aeronautics welding jig

Manufacture of an expandable welding jig for aeronautical welding assembly. Design of a specialised installation handling significant volumes of parts to be gripped (Ø>1500)...