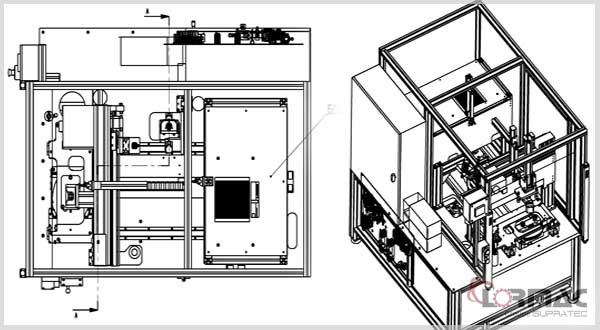

Specialised assembly machine : bonding of luminaires

Custom assembly machine designed for the assembly of the components of a public lighting system by bonding.

Requirement / Automation of production.

Automation of the lamppost head assembly process (bonding of transparent parts to the aluminium body and bolting on of cable glands).Solution / Automated bonding machine.

The assembly machine designed and manufactured by Lormac performs all stages of assembly in under 90 seconds:- Manual loading of components

- Application of a continuous bead of adhesive using digital interpolation

- Assembly of components by bonding and UV polymerisation

- Automated bolting of the cable gland

- Manual unloading of the part

The machine’s performance levels /

- A complete cycle time of only 75 seconds,

- 600 x 600 mm bonding runs

- 1000 mm main digital axis run

Further information.

This specialised bonding assembly machine was the result of the combined skill sets of Lormac and Syneo, both subsidiaries of Groupe SUPRATEC. The internal provision of all skill sets required allowed Lormac to provide a complete custom turnkey solution integrating a standard volumetric dosing system. The integration of Syneo’s high-precision dosing system into the automated process not only reduced adhesive consumption to 80 kg/year (compared to 500 kg of adhesive before), it also reduced storage times required for the finished parts. Complete polymerisation of the bond using a UV lamp takes just 75 seconds and renders the part immediately usable, the previous process required 24 hours drying time.