Automation of production processes, systems integration

- Centralised project management : study, design, manufacture, optimisation, implementation and operator training

- Turnkey services : integration of standard processes, meeting specific customer needs

- Internal skill-sets : hydraulics, electrics, mechanics, pneumatics, automation

- Quality and precision : precision, repeatability, cycle time, safety…

- Multi-sector expertise : vehicles, aeronautics, agri-business, mechanical transformation …

Examples of process automation and systems integration products :

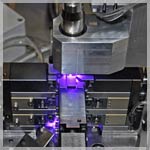

1. Automated UV bonding machine

Specialised UV bonding machine for the automated assembly of ferrites Automation of the motor manufacturing process using Syneo dosing, bonding and UV curing equipment, Syneo is a subsidiary of Groupe Supratec specialising in industrial bonding... Annual production in the order of 100,000 parts...

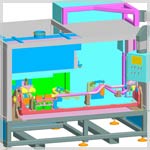

2. Complete press fitting assembly line

Study, design, manufacture and implementation of a complete automated assembly line integrating press fit units, industrial robots, bolting stations, end of process checking stations and linkage conveyors...

3. Specialised automated bolting machine

Integration of a specialised automated machine for the assembly of cylinder head covers in to a vehicle production line, made-to-measure. Specialised multi-spindle machinery and tools, end of process quality control, simultaneous tightening of 9 attachment bolts...

4. Automated bolting station, industrial robot integration

Implementation of a robotised bolting station on a production line. Turnkey solution with integrated bolting unit on a multi-axis industrial robot, bolts fed on the fly by a blower, automated change-out of production run...

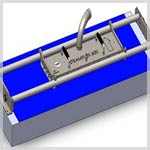

5. Integration of a steam cleaning system on a conveyor

Custom lateral movement and stopping system integrating a steam cleaning bridge. Installation over food conveyor for disinfection of conveyor belts. Ultra-flexible system covering entire length of the belt...

6. Specialised machine, puncher integration

Design and manufacture and a specialised double-punch machine. Installation of the unit on a vehicle construction line. Industrialisation of the engine production process...

7. Specialised flowdrilling machine

Design of a custom production machine using drilling and tapping equipment. Component referencing, smoke extraction, linear transfer...

The automation of a production process is merely the mechanisation of repetitive tasks.

The industrialisation of a production process by LORMAC technicians will result in the optimisation of production. The performance indicators used in the automation of a process include increased productivity (enhanced tempo) and quality, improved flow management (lower energy consumption, fewer materials and storage costs) and improved working conditions for operators.